The Moth-eye patterned sapphire substrates (the MPSS) is used in LED manufacturing for reduction of the light extraction efficiency, manufacturing cost and yield improvement.

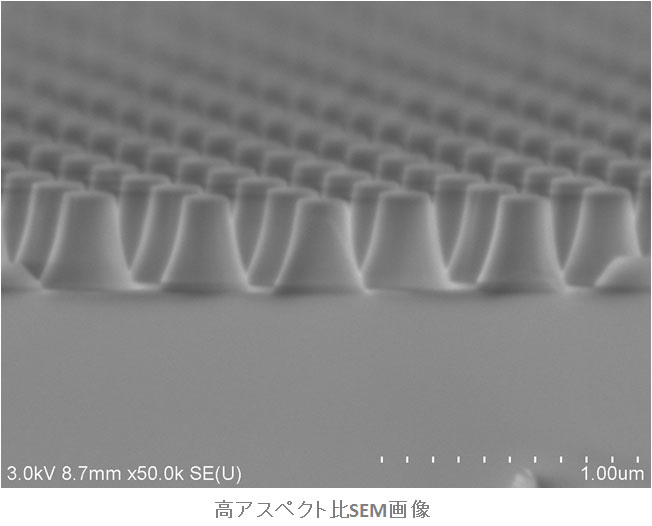

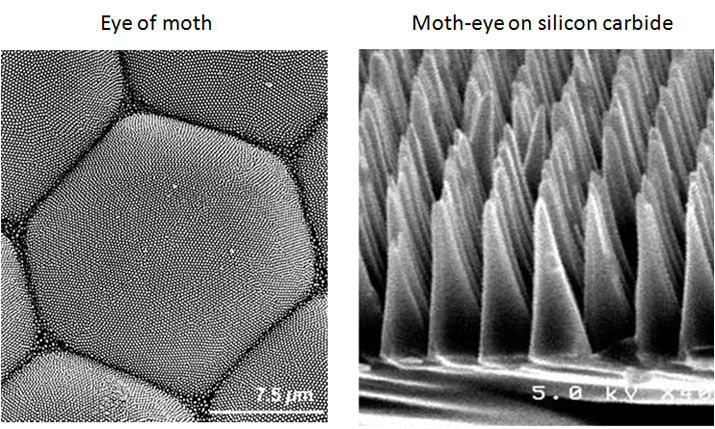

The Moth-eye Structure

In 1967, the structure on eyes of moths was discovered to have submicron-scale periodic cones. This structure is called “Moth-Eye Structure”, and is known to have almost no reflectivity.

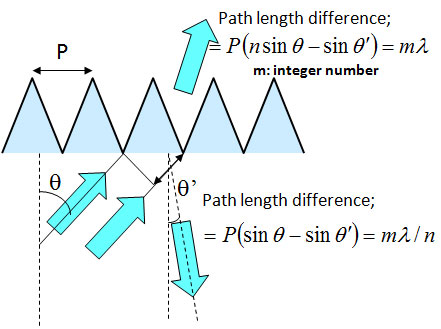

Principle

Prof. Kamiyama’s simple and ingenious idea to use a more vertical light path obtained in the moth-eye layer to minimize the number of reflections in LED chips before light escapes and thereby to reduce absorption (energy loss).

The verticalization effect

Diffraction causes reflected and transversing light to bend at the moth-eye plane

The result is a more vertical angular distribution of light in the LED.

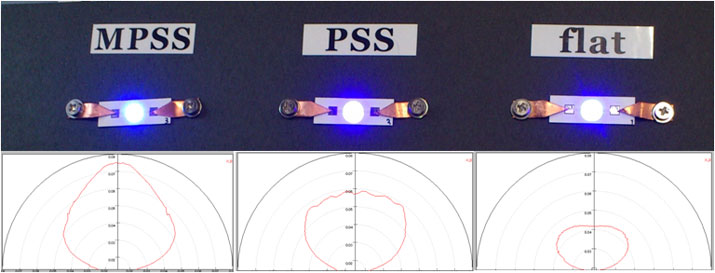

Angular Distribution

A more vertical angular light distribution is obtained in LED’s grown on MPSS compared to devices grown on PSS and flat sapphire substrates.

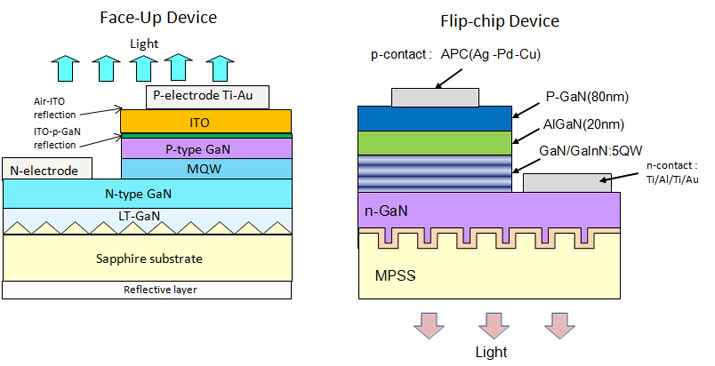

Device structures

MPSS can be applied both in face-up and flip-chip devices.

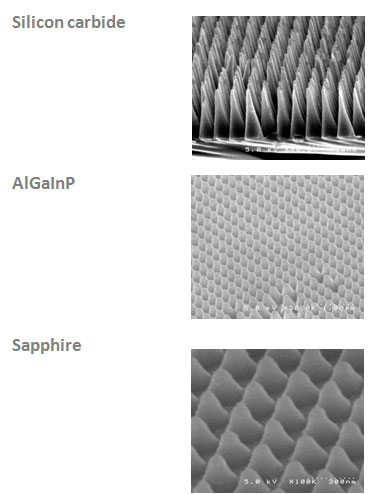

Materials

We have applied moth-eye patterning technology on SiC, Sapphire and AlGaInP substrates.

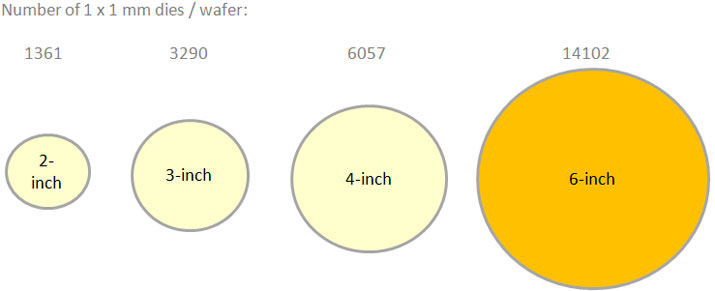

Form Factors

We are patterning 2-, 3- and 4-inch substrates today and are planning for 6-inch production in the future.

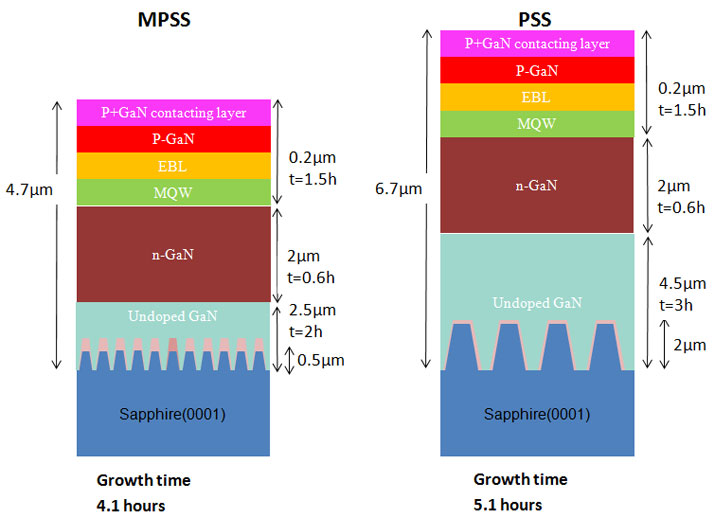

Lower GaN Cost

MPSS enables the use of a thinner undoped GaN layer than used on PSS and saves cost in production.

Applications

MPSS can be applied in blue, white, yellow, red and green LEDs.

Advantages

Using MPSS technology in LEDs has five major benefits:

- Lower energy consumption through enhancement of light extraction efficiency

- Lower cost thanks to a 2 µm thinner undoped GaN layer

- Higher device yield for large size substrates thanks to less wafer bowing

- Improved wavelength uniformity (on large substrates)

- Maintained energy efficiency also for large size devices